Electrostatic accumulation/ Charge is a common issue found in both wet and dry filtration applications including, API drugs- Fluidized Bed Dryer & Centrifugal bags Edible Oil /Palm Oil Production. AS industrial accidents point out that 1 out of every 10 explosions is due to static electricity. When powder particles with electric load are suspended in air-streams (i.e. pneumatic transport) it’s important to verify the grounding of all metallic structures (all conveying lines, connected equipment, tube sheets and filtering media). In dust collectors, the electrostatic load can grow both on filter media and on the dust cake, and it is facilitated by low moisture levels, high temperatures, high contact velocities and small particles. Materials like wood powder, grains, sugar, aluminum, magnesium, fiberglass and carbon fiber could generate explosive conditions

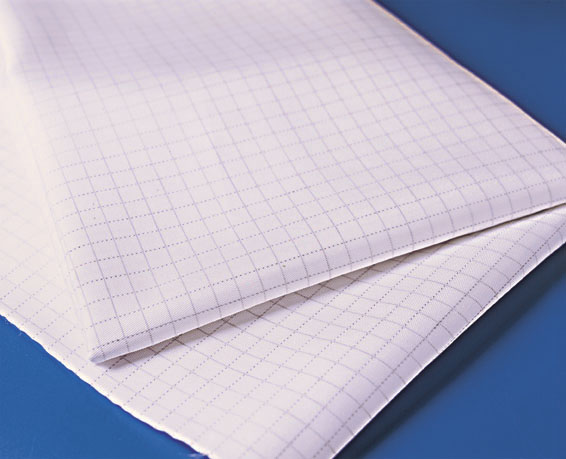

RATTAN FITERS® offers reliable antistatic filter media designed to meet the most stringent requirements in terms of safety and filtration efficiency AT RATTAN Filters®, our Development team has developed a range of media covering different polymer and yarn types. We incorporate anti-static technology woven directly into the structure of the fabric to reduce the risk of electrostatic and to guarantee a smooth filtration process. The composition is such that when properly earthed, the static charge is dissipated through the structure of the media due to its inherent electrical conductivity.