Features

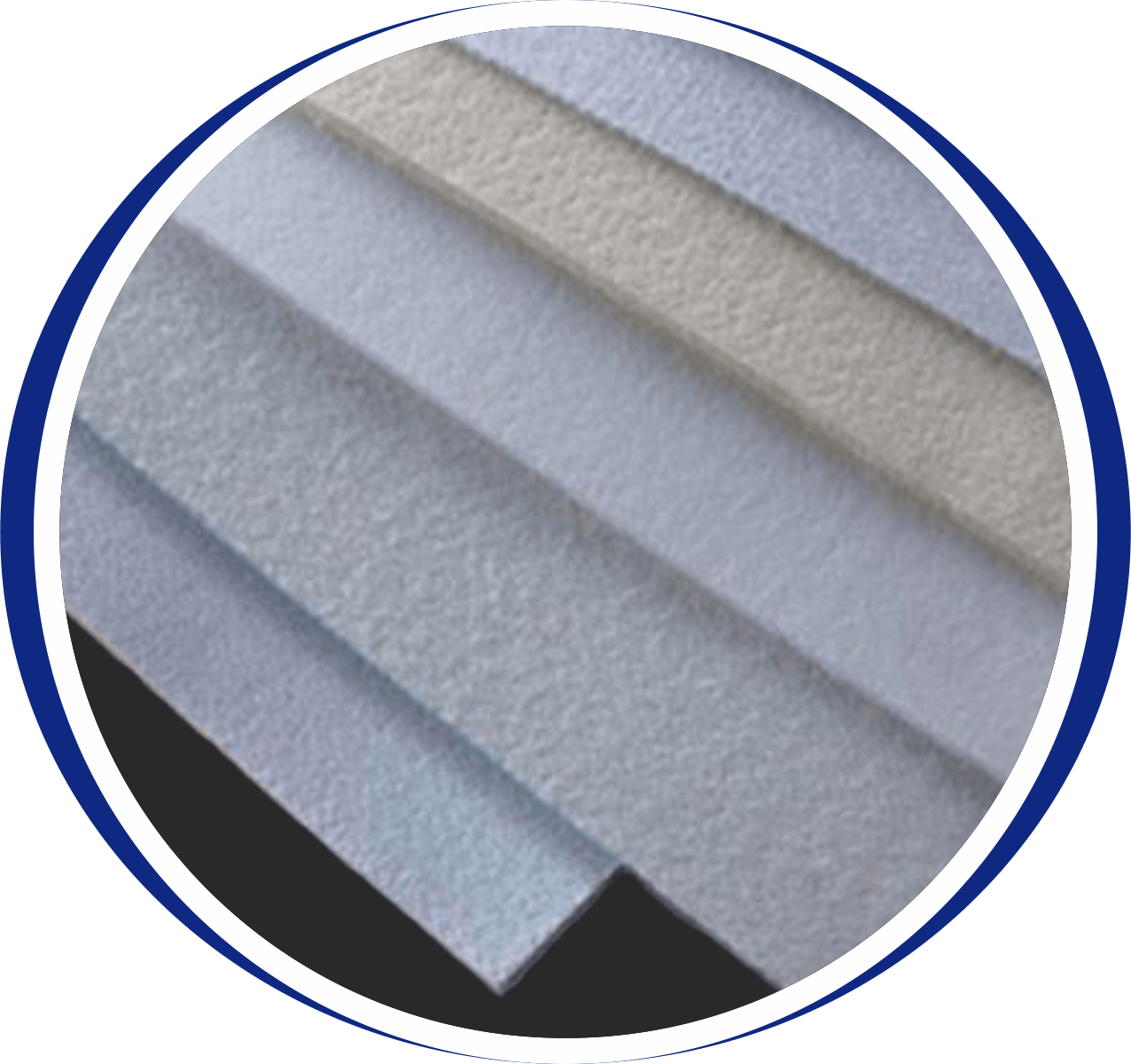

- Material : PTFE membrane laminated on superior quality reliable fabric materials such as Polypropylene, Non-Woven, Pet and Pe Non- Woven

- Breathable filtration material

- Due to homogeneous pore size, distribution is high

- It has collection efficiency and air permeability

- It is water- and wind-resistant

- It is usefully applied in chemistry and food stuff processing, electronics, mechanics, etc